Chiller Coatings

Corrosive damage to HVAC chiller components, especially tube sheets and end bells, can break down a centrifugal chiller or even shut down an entire facility cooling system! BMI can help you avoid such costly breakdowns.

BMI offers a proven chiller coatings solution, 20+ years of experience, and a reputation for providing reliable chiller coatings maintenance and repair. Our chiller coatings solutions include chiller tube sheet coatings, chiller end bells coatings, water box coating, and HVAC chiller heat exchanger and condensers epoxy coatings.

Quick Download: BMI Chiller Coatings Solutions

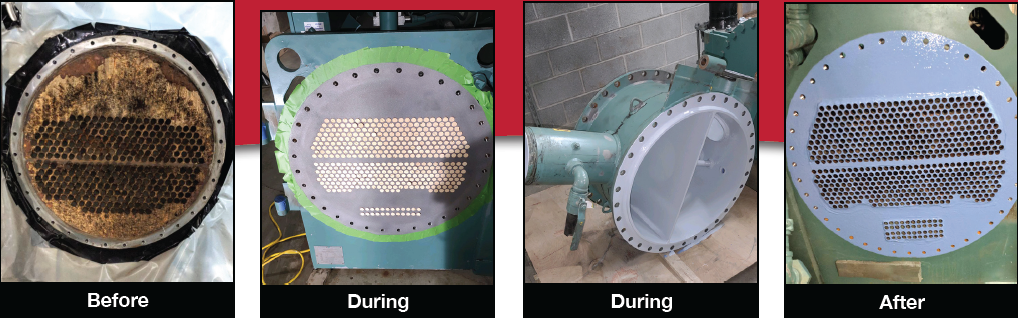

From Rusted-Clogged Chillers to Clean-Coated

The Issue

Copper tubes inserted into carbon steel tube sheets experience galvanic corrosion due to the dissimilar metals. The corrosion and loss of carbon steel effects the performance levels in a facility chiller due to water flow issues, sediment build-up and eventual tube sheet perforation and refrigerant loss.

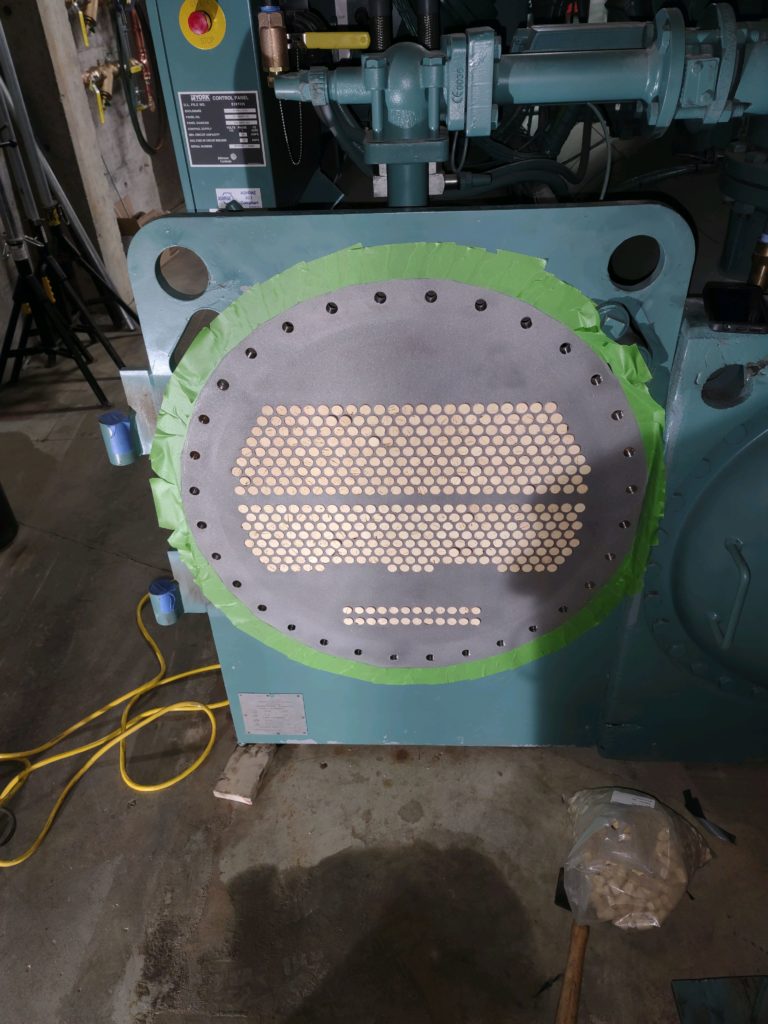

BMI Solution

Allow us to coat your chiller components with a 100% epoxy solution. We start with bead-blasting all coating surfaces to a near white metal profile, prepare the coating areas and apply our coating system. We repair all areas where corrosion and deterioration have occurred and then complete the job with a three-coat system at 10-15 mm per coat for a long-lasting solution.

Results

From rusty and clogged to a renewed look and performance, your facility chiller is back in service, running properly, saving energy, and with noticeably speedier cleaning times.

CONTACT BMI

Contact BMI today at 603-394-2188 or via email for a complimentary walk-through assessment and quote.

BMI is also New England’s go-to resource for cooling towers coatings, chiller coatings, facility epoxy floor coating, and more.