Critical Time to Assess Heat & Boiler Feed Pumps

It’s the time of year when facilities switch from cooling to heating. It’s also the perfect time to assess the condition of your heat and boiler feed pumps. With over 60 years of combined expertise in pump and motor repairs, BMI can handle any size pump for any application. Plus, we offer have a thorough […]

Time to Get Your Chiller Coating Scheduled

This is an earlier notice to get your chiller coating Chiller Coatings quoted and scheduled early. Peak chiller coating season in New England runs from December – April. By taking action early, you can avoid the rush and stress of last minute quoting, while enjoying priority scheduling and potential cost savings. BMI’s custom chiller coating solution […]

Specialty Coating Gallery Highlights

We’ve been doing quite a bit of of work this summer helping facilities control moisture issues with our custom waterproofing and specialty coating solutions. Below are a few recent examples: BMI Mechanical offers the best customized solutions for specialty coatings and waterproofing in New England, including: Air Handler & Drip Pan Coatings Chiller Coatings Concrete, […]

Spot the BMI Van Contest

We’ve cooked up a little fun this summer and we hope you’ll play along. It’s the Spot the BMI Van contest! Okay, we know it’s a little dorky but we’re super proud of our new van as it was purchased solely for our growing Pump and Motor service and sales division. It’s also the first […]

Check Out This Cooling Tower Leak

When BMI’s specialty coating crew arrived to this cooling tower they took a quick video of how much it was leaking. Click this video link to see the leak. Have No Fear, BMI Stops the Leak! Highly Effective CIM Liquid Membrane System BMI stopped the leak and extended the cooling tower’s life cycle by installing […]

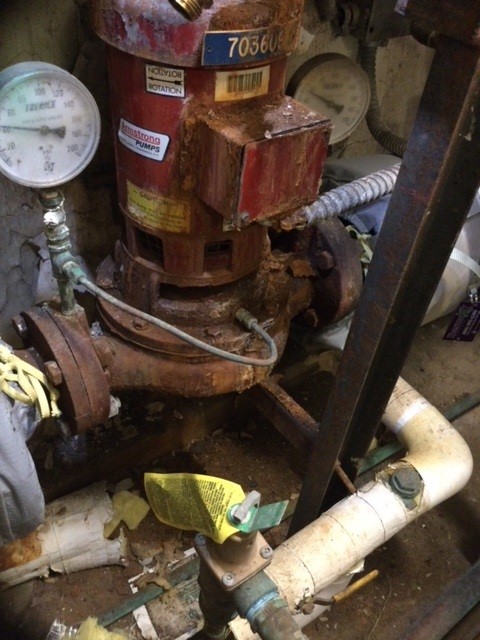

Peace of Mind with Preventative Pump Maintenance

We all know that regular pump maintenance is vital for facilities. Yet all too often, facility team members are maxed out handling the daily details of their job and are not able to be as diligent about maintenance as they prefer. This is why facilities in the Greater Boston area are turning to BMI. We […]

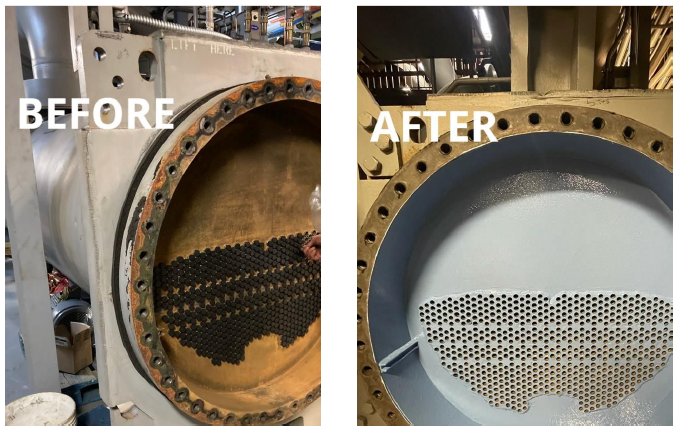

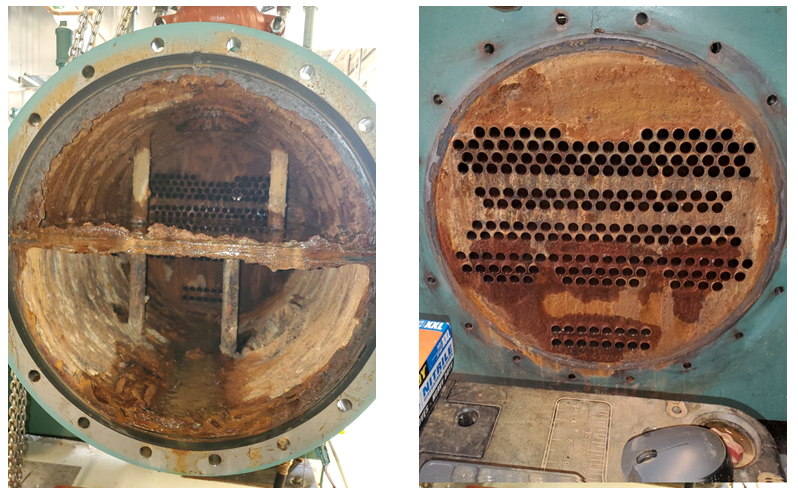

It’s Not Too Late To Avoid Chiller Downtime

We understand the importance of maintaining the efficiency and longevity of your chiller components, and it’s never too late to take proactive measures to prevent leaks, decreased efficiency, and downtime caused by corroded chiller elements. At BMI, we specialize in employing cutting-edge coating technology to repair and protect chiller components, including tube sheets, water boxes, […]

4 Warning Signs Your Facility Pump is Failing

Before a facility pump completely fails, it typically gives off warning signs. The pump failure warning signs include: Leaking. One of the most common causes of pump leaks is seal failure. Slowing speed. A worn out or clogged pump can cause pump speeds to slow significantly. Noisy and/or excessive vibration. Bearing failure, an unbalanced rotor […]

Beat the Rush on Chiller Coating

We’re sharing a friendly nudge to let us quote your chiller coating project early. Our peak chiller coating season runs from December – April. By taking action early, you can avoid the rush and stress of last minute quoting, while enjoying priority scheduling and potential cost savings. BMI’s custom chiller coating solution was developed to address […]

AHU’s – Stop Leaks

Stop Leaks Caused from Excessive Humidity & Moisture with AHU Coating I don’t know about you, but we are happy to finally see the sun! We bet you are too. After a long rainy season though your facility may already be struggling with humidity and moisture issues, especially in your Air Handling Units. Excessive […]